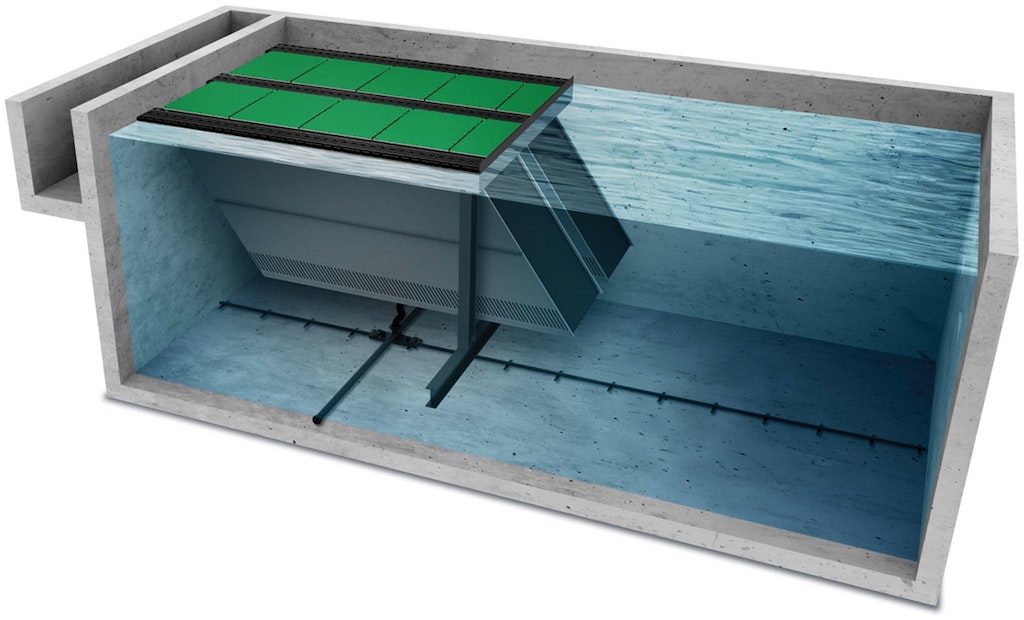

Texler clarifiers use lighter, lower-cost materials, contributing to lower capital and installation costs.

Interested in Tanks?

Get Tanks articles, news and videos right in your inbox! Sign up now.

Tanks + Get AlertsEfficient clarification is an essential component of drinking water treatment. Many water plants have existing rectangular sedimentation basins in need of refurbishing; some such facilities also need to expand, but are in sites where available land is limited.

Now Leopold, a Xylem brand, has introduced the Texler lamella clarifier, designed as a compact and efficient solution for sedimentation. It uses a series of inclined lamellae designed to fit in rectangular clarification basins, providing a large settling area within a small footprint.

With efficient solids removal, the process is built to achieve very low turbidity levels and to improve the filterability of the water. The lamella sheets are installed at a 55-degree angle; the company says the design can increase treatment capacity by up to 100% compared to conventional sedimentation.

While lamella clarifiers (also called plate settlers) have been around since the 1970s, the Texler uses different materials of construction, making it lighter and lower in capital and installation cost. The trough covers have an integrated V-notch weir design to provide even flow. Matt Schomaker, a treatment regional manager with Xylem, talked about the technology in an interview with Treatment Plant Operator.

What was the reason for bringing this product to market?

Schomaker: Over the last 10 years we have seen growing interest in lamella clarification systems. One of the main motivations is that plate settlers can take an existing sedimentation basin and essentially double its flow. The other major benefit is that when building a new treatment facility, the clarification footprint can be reduced as much as 80%.

What is the basic difference between lamella clarification and traditional methods?

Schomaker: Sedimentation systems have a flocculation process followed by coagulation. The water then goes into a larger sedimentation tank where the particles settle out. Without a plate or tube settling system, it takes three to four hours of detention time for the solids to settle out. An inclined plate system can reduce that time to as low as 25 minutes in some applications. It’s a very simple technology. There are no moving parts in the clarifier itself; the only moving parts are in the sludge collection mechanism beneath the plate settler.

How does the lamella settling process work?

Schomaker: It essentially adds surface area to the basin by providing the plate settlers inclined at a 55-degree angle. The coagulated water comes into the side of the system and travels up the plate and out through an effluent trough. The solids settle out upon contact with the plates and then settle down to the floor of the basin.

What makes the Texler lamella clarifier different?

Schomaker: The key advantage of the Texler system lies in the materials of construction. Traditional plate settler systems are made of all stainless steel components. The Texler uses HDPE for the side panels, and the plates are formed from an NSF-certified HDPE geotextile material. This geotextile is hydrophobic in nature, so it actually repels water. This helps to reduce material accumulation on the sheets, so that there is less need for cleaning. UV covers absorb 90% of the light and help minimize algae growth.

What other advantages do these construction materials provide?

Schomaker: A Texler system will be about one-third the overall weight of a stainless steel plate settler. That means much lighter support structure is required, and there is a cost benefit in the materials themselves. So a Texler system will have lower capital cost, and lower field installation cost due to the reduced support structure.

What else is different about this technology?

Schomaker: It has a stainless steel effluent trough. That trough has cover with a V-notch weir to control the flow. The cover keeps wildlife from nesting in the troughs, and it also serves as an access point; operators can use it as a catwalk. It keeps them from coming in contact with the water surface if they need access to hose down the sheets or do any maintenance.

How easily can this technology be retrofitted to existing basins?

Schomaker: It is very conducive to retrofit in rectangular sedimentation basins. We can adapt the width of the lamella sheets to optimize the effectiveness of the existing basins. We can accommodate depths of 5, 8 or 10 feet. In any existing rectangular clarifier, a Texler system can be expected to increase efficiency and production.

Are there any sweet spots for this technology in terms of flow rate or source water characteristics?

Schomaker: Traditionally, we are looking at system flows larger than 1 mgd. It also applies to smaller steel tank systems. In terms of source water turbidity, we have done substantial testing in applications from 2 NTU, to 50-60 NTU, and with flashes up to 100 NTU. It can be used in reservoir systems and could also function effectively with river source waters.

What has been done to prove out this lamella clarifier?

Schomaker: We developed the concept about four years ago, and we have gone through a series of “toll gates” we use in developing any product to make sure the design is appropriate and the value is there to move forward. We have also done significant testing. That includes piloting at a site in western Pennsylvania for more than two years, on a fairly flashy river source water. With raw water turbidities from 2 NTU to 60 NTU, we’ve seen less than 1 NTU coming out.