The BIOCOS process is a hybrid activated sludge system in which all mixing and recycling are driven by blower air, significantly reducing energy usage.

Interested in Laboratory?

Get Laboratory articles, news and videos right in your inbox! Sign up now.

Laboratory + Get AlertsIn today’s economic and social climate, federal and state agencies are tightening wastewater discharge permits and pushing clean-water facilities to adopt more sustainable practices.

In line with that, many treatment plants are upgrading their systems to match or outperform the new regulatory limits. One example is the Edgemont Ranch Metropolitan District, 6 miles northeast of Durango, Colorado.

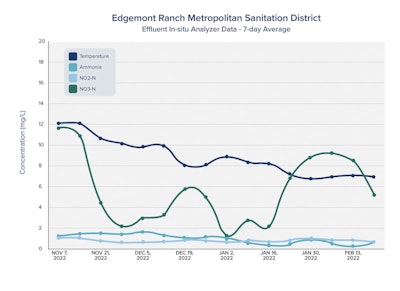

The district’s treatment facility (175,000 gpd design, 138,000 gpd average) is using an innovative treatment solution as part of an upgrade that has improved operations and enabled compliance with more stringent limits. Besides improving effluent quality, the technology, BIOCOS from World Water Works has enhanced energy efficiency.

Seasonal stability

The Edgemont Ranch facility services a 710-unit housing development consisting of 35-year-old single-family homes that previously were hunting cabins. When originally built, the cabins all had septic systems.

Edgemont Ranch lies in the watershed of the Florida River, a tributary of the Animas River. Downstream of the treatment facility are agricultural irrigation reservoirs that experienced algae blooms, possibly attributed to the district’s nutrient-rich effluent.

The Florida River is considered the largest contributor of E. coli to the Animas River, largely because of many septic systems in the area. As a point source of pollution Edgemont Ranch saw its discharge limits for ammonia, total inorganic nitrogen and other contaminants tightened by the state Department of Public Health and Environment.

The treatment facility previously used a connected series of aerated and non-aerated lagoons to treat wastewater. Lagoon operation was simple but lacked flexibility, and energy usage was high because of older equipment, including two blowers that had to run continuously to keep the aerated lagoon well mixed.

A better design

Because lagoon-based systems are vulnerable to cold temperatures, Edgemont Ranch was unable to nitrify for several months of the year in its high-mountain climate, where water temperatures could drop close to freezing. Small upgrades such as covering over the lagoons could not meet stricter effluent standards.

As a remedy, the district looked to the BIOCOS technology, a hybrid activated sludge system designed to deliver more thorough treatment than conventional systems. The system was designed by Element Engineering based in Lakewood and installed by Integrated Water Solutions of Longmont.

It consists of two aeration tanks (AIR tanks) hydraulically connected to an alternating pair of sludge recycling and settling tanks (ALT tanks). The design is built with redundancy in mind, enables continuous wastewater processing, and promotes removal of BOD, TSS, TIN and total phosphorus.

All mixing and recycling are driven by blower air, significantly reducing energy usage and maintenance while simplifying treatment. Multiple SCADA-driven aeration control loops based on dissolved oxygen, ammonia and ammonia versus NOx allow operators to set concentration thresholds and provide flexibility to meet the new discharge limits.

Hybrid process

The BIOCOS system was started up in July 2022. Raw wastewater passes through a standard headworks including a 6 mm screen and a grit removal system. The preliminary-treated water is pumped to a BIOCOS SEL tank, an unaerated portion of the AIR tank.

From there, the blower delivers process air to the AIR tanks, supporting the growth and cultivation of beneficial bacteria. The blower air is also used to create an airlift that moves the thickened sludge layer from the bottom of the ALT tanks and back into the SEL tank, where it mixes again with the influent wastewater.

The system includes the inDENSE selective sludge wasting process, which uses hydrocyclones. This form of wasting retains the heavier, easier-to-separate bacteria while the lighter, less desirable populations are discharged as waste activated sludge.

After settling, the cleaned water exits the ALT tanks and runs through a UV disinfection system. The final effluent, meeting all permit limits, is discharged to the Florida River.

The process has reduced energy costs by nearly 50% while providing a high level of treatment. It enables the facility to meet effluent limits year-round.

The discharge permit requires 20 mg/L TIN; the BIOCOS process achieves 1.5 to 2.0 mg/L. It also removes more than 95% of BOD and TSS. The advanced activated sludge process has given the Edgemont Ranch facility greater operational flexibility and environmental resilience.

About the author

Daniel Dair (dair@worldwaterworks.com) is vice president of innovation with World Water Works.