Interested in Odor Control?

Get Odor Control articles, news and videos right in your inbox! Sign up now.

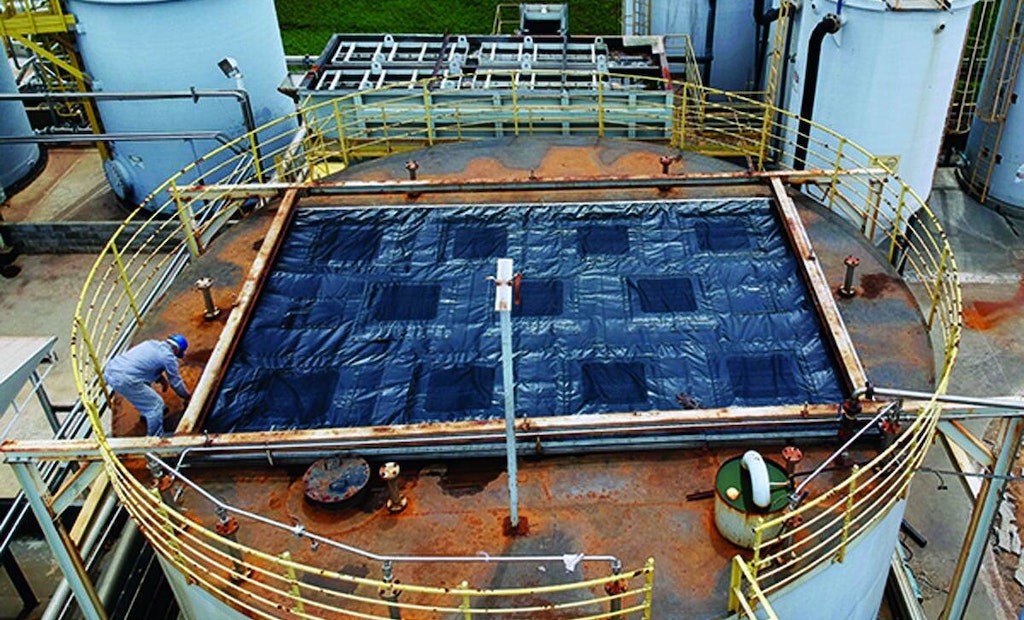

Odor Control + Get AlertsGeomembrane covers solve odor issue in wastewater plants

Problem: Laguna Madre Water District in Port Isabel, Texas, sought to eliminate odor complaints after a high-end housing development was built next to the primary treatment plant. “We had all this new construction getting closer and closer to the plant, and we were concerned about keeping the nuisance odors within our buffer zone,” says Charles Ortiz, district engineer. Offsite odors at the worst point averaged above 88 ppm just above the channel surface; peak spikes registered above 860 ppm.

Solution: Anue Water Technologies provided a breathable geomembrane solution, enabling effective treatment without changing the plant footprints or operations. The flexible geomembrane system has a breathable design where pockets in the material contain replaceable carbon-infused filters that allow water and air to pass through, but trap the odorous compounds. No special equipment was needed to install the customized solution.

Result: The membranes lowered odor levels to an average of 1.2 ppm; all off-site odors were eliminated. “We still have a little tweaking to do here and there — nothing is perfect, but as odor controls go, I would say that the system has done its job,” says Ortiz. 760-727-2683; www.anuewater.com

Treatment plant expansion addresses multiple contaminants

Problem: The City of Tucson water treatment plant was treating 1,4-dioxane using a UV advanced oxidation process with eight granular activated carbon vessels for peroxide quenching. Water quality testing revealed significant PFAS contamination, requiring the plant to expand capacity for the longer empty-bed contact time PFAS removal requires.

Solution: AqueoUS Vets provided the treatment and delivery systems, which included two 12-foot-diameter lead-lag granular activated carbon systems, with two pressure vessels per system. The systems have an empty bed contact time at 930 gpm of 5 minutes per vessel, and 10 minutes per system.

Result: While there are no state regulatory limits for PFAS in Arizona, the EPA issued interim updated health advisory levels for PFOA and PFOS in June 2022, with updates expected in early 2023. The health advisories are currently 0.004 parts per trillion for PFOA and 0.02 ppt for PFOS. Since July 2020, the city has been removing PFAS to nondetectable levels. 925-331-0573; www.aqueousvets.com

Mini analyzer helps plant fine tune sodium bisulfite use

Problem: Dechlorination equipment at the South San Francisco – San Bruno Water Quality Control Plant required frequent maintenance and experienced drift and persistent fouling. Plant operators overfed sodium bisulfite to ensure that treated water was thoroughly dechlorinated before release into San Francisco Bay, making bulk chemicals one of the plant’s top five expenses.=

Solution: Plant leaders chose the ChemScan mini Sulfite Analyzer for its large blockage-resistant sample tubing, internal self-cleaning, simple field-adjustable calibration and low cost of ownership.

Result: The analyzer’s reliability took the guesswork out of dechlorination and reduced sodium bisulfite usage, saving $53,000 per year. 800-446-7488; www.in-situ.com/us/chemscan-mini-analyzer

Injection system solves algal toxins issue at plant

Problem: The source water for Collins Park Water Treatment Plant in Toledo, Ohio, comes from the western basin of Lake Erie. In 2014 the lake experienced seasonal toxic algal blooms.

Solution: The city chose a multibarrier approach with powdered activated carbon, ozone, and chlorine. The 40 mgd plant expansion included two identical ozone contactor buildings each with two dissolution basins. To introduce and mix ozone, venturi sidestream injection and pipeline flash reactors from Mazzei Injector were chosen. Together they deliver at least 95% mass transfer efficiency. The reactors require just a few feet of pipeline for mixing and were sited in a three-story stack that minimized the footprint.

Result: The multibarrier system removes 99.7% of the toxins while controlling taste and odor; removing endocrine-disrupting compounds, pharmaceuticals and personal-care products; reducing disinfection byproducts; minimizing polyaluminium chloride usage. Lower PAC usage for taste and odor control reduced operating costs. 661-363-6500; www.mazzei.net

Chemical treatment plan aids facility’s optimization needs

Problem: A customer of Operators Unlimited in the aerospace, building technology and performance materials industries faced challenges with system efficiency and wastewater regulation compliance in a newly upgraded facility. The upgrade added two cooling towers. The customer needed chemical treatment to accommodate increased capacity and optimize chemical usage while optimizing efficiency, cost-effectiveness and microbiological control.

Solution: Operators Unlimited prescribed a microbiological control chemical treatment plan to optimize cooling tower operation. The plan alternates oxidizing and a non-oxidizing biocide, providing greater microbiological control than common oxidizing treatment products alone, while maintaining industry standards for biological protection. Removal of the microbiological impurities limits damage they could cause to the cooling tower system.

Result: The plan helped the facility comply with permit requirements while tailoring chemical treatment to the application. 864-228-1131; www.operatorsunlimited.net

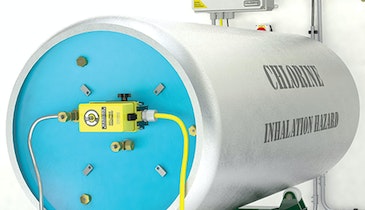

Emergency gas scrubber used to rectify chlorine gas leak

Problem: An alarm that went off at O.B. Curtis Water Treatment Plant in Ridgeland, Mississippi, indicating a chlorine gas leak. All personnel were evacuated and multiple agencies responded. First responders along with plant maintenance staff identified three leaking valves and secured the area.

Solution: The plant installed a FOC-1 Fiberglass Emergency Gas Scrubber from Purafil with Chlorosorb dry-scrubbing media next to the chemical building. It is designed to contain the entire contents of a fully loaded 1-ton chlorine cylinder in a worst-case release. This outperforms the requirements of the Uniform Fire Code. The building has air scrubbers to keep chlorine from escaping the building.

Result: Instead of toxic liquid caustic to neutralize gases, the EGS uses non-toxic, dry-scrubbing media. The process removes chlorine by adsorption, absorption and chemical reaction. Chlorine gas is trapped within pellets where an irreversible chemical reaction changes it into a harmless solid. During the chlorine leak the EGS immediately began to remove the chlorine gas, minimizing the risk to employees and the community. No injuries were reported, and no other evacuations of the surrounding area were needed. 800-222-6367; www.purafil.com

County treats disinfection byproducts with ion exchange treatment

Problem: The construction of a new well prompted Seminole County to address hydrogen sulfide regulations by the Florida Department of Environmental Protection. Struggling with disinfection byproducts from TOC and bromide in the water, the county began a pilot study using ozone oxidation to address the hydrogen sulfide and reduce disinfection byproducts. The county partnered with Tonka Water to develop an anion exchange system to treat groundwater.

Solution: The county chose an Organix ion exchange treatment system from Tonka Water, a Kurita America Brand, to address TOC. The process consists of six 12-foot-diameter ion exchange vessels containing anion exchange resin and support gravel. Water is pumped directly from the wells through the ion exchange system to storage and the distribution system. The fully optimized system closely matches resin capacity with control of brining and regeneration of the media. This enables reduction of brine waste and backwash water.

Result: The plant is meeting expectations since its commissioning. 866-663-7633; www.kuritaamerica.com