Interested in Dewatering/Biosolids?

Get Dewatering/Biosolids articles, news and videos right in your inbox! Sign up now.

Dewatering/Biosolids + Get AlertsA major lift station was under construction to replace an older station in the wastewater collection system in Sarasota, Florida.

The new station would eventually carry about a third of the total flow to the city’s wastewater treatment plant. During testing of a 36-inch influent line that crosses Hudson Bayou, city crews discovered significant groundwater intrusion through several holes, breaks and joint failures. This infiltration would overload and stress the treatment system, wasting capacity and shortening the life of plant equipment over time.

The first effort to repair the line was a trenchless epoxy-impregnated liner. While this largely nondisruptive repair has worked in similar conditions, in this case it failed to stop the water intrusion. A second effort involved injection of a two-component, fast-reacting chemical grout to seal the pipe from the exterior. This also failed.

After considering traditional dig-and-replace repair as the third option, the DHIG, or deep horizons general grouting, chemical injection process was chosen. The method was successful on the Sarasota project and was also employed effectively on another project in nearby Hillsborough County.

A new approach

Injecting chemicals to stabilize, lift, seal or compact weak soils and rocks is not new. Polyurethane grout has been used for that purpose since the 1960s. However, the process has limitations for asset owners as well as installers.

Historically, grout injection has been limited to depths of 20 feet or less, and the pipe in question lies deeper. As the material is injected, it begins to cure inside the injection tube. While the cure rate can be accelerated or slowed down by regulating the chemical temperature, that control is short-lived.

The deeper or longer the injection tube, the longer time the chemical has to cure before exiting the tube. In the meantime, the diameter of the injection tube effectively shrinks as cured material bonds to the tube wall. Furthermore, the deeper the injection, the more the chemical can lose effectiveness as it cools upon leaving the tube.

DHIG, developed by Polymer Technologies Worldwide, is a method of chemical grouting that enables injection at depths far exceeding previous limits. In Sarasota, the company successfully injected its product to seal a leaking effluent line with an invert depth of about 35 feet and an injection depth of 45 feet.

City officials in Sarasota rejected dig-and-replace as a third repair option for the extensive disruptions and inconvenience it would cause, to avoid an additional $9 million to $12 million in additional costs, and to avoid extending completion time by another year for work already late and over budget.

The DHIG method sealed the pipe leaks while enhancing and helping stabilize the foundation of the lift station structure. Furthermore, trenchless process required a small footprint, did not disrupt the surrounding area, and was completed while lift station construction continued.

Proof positive

Another lift station project, at Symmes Road in Hillsborough County, further demonstrated the value of the DHIG method. Cracks in well inlet pipes in the station and some other damage was caused by about four inches of settling of the cover slab.

Standard testing found that soils near the station, 18.5 to 28.5 feet below the surface, were very loose. The station wet well measures 8 feet in diameter and 30 feet deep. To excavate and repair the station would have meant a large area of disturbance, possibly affecting a residential community, underground utilities and possibly Symmes Road itself.

After injection using DHIG, standard ground borings showed that the injected material did not expand beyond the lift station property. Injecting with 2,623 gallons of polymer through four injection points at depths from one to 45 feet below grade yielded these results:

- Soils around the wet well were significantly strengthened.

- Soils outside the lift station footprint showed insignificant change in soil stiffness, indicating no adverse effects to surrounding properties or structures.

- The grout filled voids, stopping leaks from eroding the area around the system, and stopping water intrusion that had also caused erosion.

A post-injection analysis and report from Integrity Drilling & Geophysical Services showed good control of the material in that none of it encroached on neighboring properties. In addition, soil adjacent to the grout was compacted and stabilized.

Rig operation

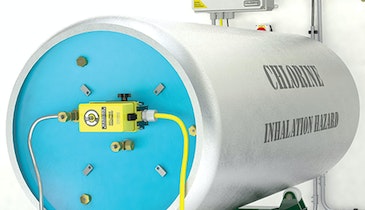

The DHIG rig is used in part to advance the injection casing to the desired depth. The 3-inch-diameter steel casing, threaded on each end, is advanced as new sections are threaded on as needed. It takes increasing power to turn the casing as it advances; the strength and adhesive properties of the material being advanced through the casing also affect turning power.

Upon reaching the desired injection depth, the rig withdraws the casing as the polymer is injected. Care is taken to advance at an appropriate rate that avoids fouling of the casing with the polymer, although not so fast that the polymer is under-injected.

To inject the polymer, a special nozzle is advanced through the casing and attached to the drilling head at the casing tip. The casing head and attached chemical feed lines are lowered carefully, using a lowering/turning bar, to avoid fouling the lines or damaging the injection nozzle. That bar is then rotated to lock the equipment to the head. As the casing is withdrawn, the lowering bar is removed in sections, just as the casing is removed.

How it works

The significant advantage of DHIG is that there is no theoretical limit to the depth at which the material can be successfully injected. That is because the material is combined at the tip of the casing, enabling full material strength to be achieved where it’s needed rather than inside the feed line.

Another benefit is that the material can be injected from a lateral point to avoid interfering with nearby project activity. This limits time, cost and impacts to the public and the environment. For example:

- A leaking cross drain can be sealed without closing down a busy highway or interstate system.

- A lift station can remain in operation while a leaking influent line is sealed.

- Retaining walls can be sealed at depth without excavation or injection from the face, which can further weaken the wall.

- Abandoned wells can be sealed so that the well can be put back into service if need be.