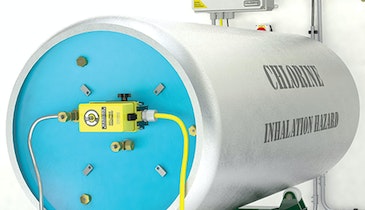

Chlorine analyzers like this APFCL unit from Blue-White Industries operate without reagents, saving money and maintenance.

Interested in Pumps?

Get Pumps articles, news and videos right in your inbox! Sign up now.

Pumps + Get AlertsChlorine is a reliable and widely used disinfection agent for drinking water. When dosed correctly, it kills a broad range of pathogens and is safe for people and animals to consume.

Accurate dosing is essential, since inadequate chlorine might not kill the most harmful pathogens, and too much will give the water an unpleasant taste or smell. For that reason, water plant operators monitor chlorine levels before the water enters the distribution system.

Measuring chlorine isn’t as simple as finding that the water contains X parts per million. The most critical value is free chlorine — the amount available to actually destroy pathogens. The higher the free chlorine level, the greater the disinfecting power.

A proven way to measure chlorine in real time is with analyzers, such as those supplied by Blue-White Industries. Since late 2022 the company has offered two such analyzers: the APFCL for measuring free chlorine, pH and temperature; and the APH2O Multi-Parameter, which measures the same three parameters plus ultra-low turbidity.

Both help operator consistently maintain the desired level of free chlorine in the water going out to customers’ taps. Patrick Murphy, vice president of operations with Blue-White, talked about the instruments in an interview with Treatment Plant Operator.

TPO: Are these your company’s first analyzers?

Murphy: Yes. Previously we focused mostly on metering pumps and flowmeters.

TPO: What was your motivation for introducing these chlorine analyzers?

Murphy: We discovered that our customers always had some kind of analyzer to measure the quality of finished water, whether turbidity or chlorine levels. Many customers asked us to offer analyzers, and so we decided to create those products for them.

TPO: What makes these products different?

Murphy: For chlorine analysis we use Bare-Gold electrodes, which require no reagents. No chemical needs to be put into the water to cause a reaction. The electrode itself collects the information needed to give the proper free chlorine reading. In addition, the devices have no membranes, which can become fouled and lead to false readings.

TPO: Why is it beneficial for the analyzers to operate without reagents?

Murphy: Reagents are expensive and can be hazardous and time-consuming to use. They are something that has to be constantly used and cleaned out. With our devices the gold electrode can simply be cleaned and put right back into the sample. Gold also resists electrical interference.

TPO: Do the instruments also measure total chlorine?

Murphy: Yes. The free chlorine measurement is important because users need to know they have effective disinfection as the water runs through the piping system. Total chlorine is important because they also need to make sure the combined chlorine in the water is not at an excessive level.

TPO: What is the exact mechanism by which the electrode converts the chlorine level into a readout on the analyzer?

Murphy: A voltage is applied across the electrode. The voltage causes an electrochemical reaction, which then generates an electric current. The amount of current generated is directly proportional to the amount of chlorine in the water.

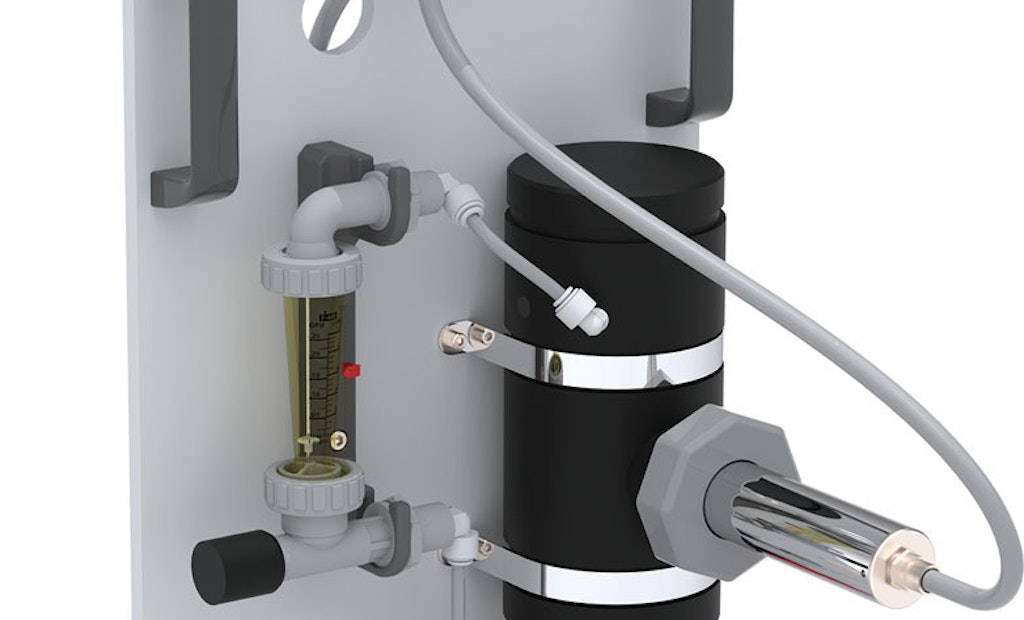

TPO: How does the multi-parameter unit measure turbidity?

Murphy: Turbidity is measured by a second sensor, which uses a light-scattering method. A warm white light from an LED is sent into the sample of water, and the amount of light scattered by particles in the water is measured. More light is scattered as turbidity increases.

TPO: How and where are these analyzers deployed?

Murphy: The devices are housed in a building or a lab. They are not completely inline; they are on the side. Typically a valve opens to let a sample flow into a reservoir. The electrode then does what is necessary to collect the information needed for a proper chlorine reading.

TPO: What must be done to install and calibrate the instruments?

Murphy: You put the electrode into a reference sample that we provide and calibrate against that. Once you do that, the sensor is calibrated and will give you the proper reading on actual samples. Our sensors have a compensation algorithm for temperature and pH.

TPO: What maintenance is required for these devices?

Murphy: The only required maintenance is periodic cleaning of the electrode. If properly cleaned, the electrode will deliver accurate results for a very long time. Also, our flat bubble pH electrode design reduces potential for fouling. It provides a scrubbing action on the electrode to maintain cleanliness.

TPO: How do users interact with the instruments?

Murphy: Depending on the model, we have a touchscreen display or a 2.8-inch screen with a touchpad. They are simple to operate. Users just need to decide what they want to display on the screen, whether chlorine levels, pH, temperature or multiple parameters.

TPO: How easy is it to learn how to use the touchscreen?

Murphy: It’s very intuitive. We try to make all our products simple, almost to where they don’t require a manual. A customer should be able to turn it on and instinctively know what to do with it — almost like when you get a smartphone.