Interested in Headworks?

Get Headworks articles, news and videos right in your inbox! Sign up now.

Headworks + Get AlertsScrew conveyors provide a reliable means to move semi-solid materials like sludge and screenings. These systems not only transport the materials but also often offer additional features such as thickening, washing and compacting. With concerns about energy efficiency, ease of maintenance and operational effectiveness at the forefront, the wastewater treatment sector is seeking systems like those below, which are being engineered to perform multiple tasks while minimizing their footprint and operational costs.

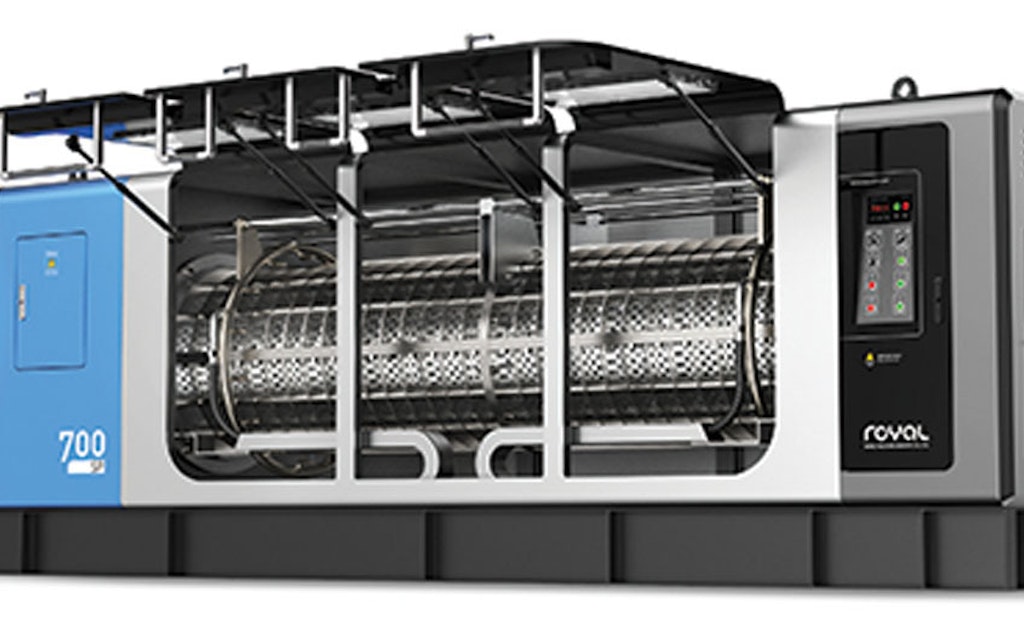

Charter Machine Royal Screw Press

Charter Machine’s Royal Screw Press offers a small footprint and high efficiency design that has very low power consumption with a higher throughput. Using an integrated thickening drum, the system can concentrate feed solids up to 5% DS. The complete skidded system is ultra-quiet, large capacity and low-maintenance. The removable wash-water nozzle ring travels, with its self-cleaning nozzles, laterally the length of the drum and gives a maximum clean with minimum amount of water. The sleek skidded design includes controls, drum thickener, sludge concentrator tank, sludge pump and screw press.

732-494-5350; www.chartermachine.com

Headworks International Screwpactor

The Headworks International Screwpactor shafted spiral washer compactor is available in three models for wastewater screenings, washing and handling applications. It is designed to receive screenings through conventional conveyance or sluicing applications. Solids enter through an inlet hopper and are conveyed by a shafted spiral where organics are washed and reintroduced into the treatment process. The washed screenings are conveyed through to a press zone where they are compacted into plug form and discharged into a bin or dumpster. Shafted Spirals are available in alloy or stainless steel. It offers throughput capacities up to 250 cubic feet per hour, and is capable of handling bricks, plastics and timbers. Optional heat tracing and continuous bagging units are available.

713-647-6667; www.headworksintl.com