Interested in Headworks?

Get Headworks articles, news and videos right in your inbox! Sign up now.

Headworks + Get AlertsGoleta Sanitation District's Water Resource Recovery Facility serves 95,000 residents along the central coast of California, neighboring the city of Santa Barbara. The WRRF has a design treatment capacity of 9.5 mgd dry weather flow, treating 4.2 mgd on average. Built in the late 1940s, GSD has continuously evolved to meet regulations, population and economic growth.

Like most WRRFs, GSD navigates the operational upsets that soaps, detergents and disinfectants create for biological wastewater treatment. When COVID-19 arrived in March 2020, the district faced the perfect storm of drought conditions reducing influent flow and higher concentrations of surfactants, like quaternary ammonia compounds, from pandemic-conscious households using more detergents and disinfectants. While the district's industrial program addressed surfactants, it needed an onsite surfactant solution for this new, indirect source.

Not their first rodeo

The global pandemic wasn't GSD's first encounter with surfactants harming their treatment process. "Our issue with surfactants started in 2016, at the peak of the last major drought," says John Crisman, then GSD's operations manager. "The governor instituted mandatory water conservation and there were upsets to the wastewater plant, which we determined to be from airport and bus lavatories." These slugs of surfactants from local industry led to costly operational expenses and risked permit violations. Fortunately, offering alternatives and best management practices to these point-source industrial dischargers addressed the surfactants' effects on the WRRF's biological treatment. The plant returned to typical operations.

Scrubbing surfactants

"The main issue with surfactants is that they interfere throughout the multi-step process," says Crisman. "Reducing clarifier effectiveness, inhibiting biological treatment process, increasing chemical demand and impacting our ability to reclaim and recycle water, which is critical during drought."

Surfactants inhibit biological treatment through a combination of decreased oxygen transfer, toxicity to nitrifying microorganisms and the increased cost associated with overcoming these treatment barriers. During the pandemic, detergent and soap use skyrocketed, while the community tried to conserve water in drought-stricken California. Unfortunately, there were no "bolt-on" surfactant treatment methods to address surfactants directly at treatment plants. With impending changes to their discharge permit, GSD began considering a multi-million dollar plant upgrade to manage the issue.

The clock was ticking, as neighboring communities made the news for severe violations caused by pandemic surfactant levels interfering with biological treatment. Fortunately, John read a TPO article about how Moleaer's nanobubbles-as-a-service solved Fallbrook Public Utility District's surfactant problem.

Specialized solution

High surfactant levels made operating Fallbrook PUD's 2 mgd treatment plant ineffective and expensive. Hoping for a resolution, Fallbrook installed Moleaer's nanobubble generator between their headworks and primary clarifier. Operations staff noted that raw wastewater concentrations of quaternary ammonia compounds found in non-bleach surfactants dropped 78% in the primary clarifier effluent. The reduced surfactant levels caused primary clarifier effluent COD to drop 61% below previous performance levels.

"Since this was an issue I'd been following for a long time, I knew there weren't many other options (to treat surfactants). And if there were options, I'd already tried them," says Crisman. "Reading about the specific actions that Moleaer takes to remove surfactants from the wastewater, and the fact that it was chemical-free, met all the other objectives Goleta would strive for, regarding energy and chemical use reduction."

Due to their size, nanobubbles exhibit unique characteristics that improve many physical, chemical and biological processes. While 2,500 times smaller than a grain of salt, their physical properties produce the hydroxyl radical, a strong oxidant. Hydroxyl radicals break down FOG and surfactants, improving wastewater quality without chemical addition. NBs also slowly deliver dissolved oxygen to their environment, eliminating the anaerobic conditions that cause process upsets, degrade plant performance, and generate odor and corrosion compounds like hydrogen sulfide.

In May 2022, GSD installed a Moleaer six-inch, 2,700 gpm nanobubble generator (NBG 6) after the WRRF's fine screening and grit removal, but before the primary clarifiers. "Working with Moleaer, we discussed the potential benefits for our plant. The biggest benefits would come from treating in the front of the plant, after screening, to see effects throughout the process," says Crisman. GSD piloted the system for three months to experience the nanobubbles’ effects on three sludge retention time cycles. The pilot required a rental pump, Moleaer's NBG 6 system, and 30 minutes of maintenance per month from operations staff.

Real results

Overnight, noticeable changes emerged at the WRRF. "One of the immediate observations was the lack of odor at the primary clarifiers and equalization basins," says Crisman.

Over the three-month trial, GSD saw many wastewater quality parameters improve. The nanobubbles helped break emulsions in the raw wastewaters, providing a better compacting primary sludge blanket and a clearer supernatant. The lab results confirmed the observations: there was a 10% increase in TSS removal at the primary clarifiers. GSD's staff visually observed that foam — a telltale sign of surfactants — had subsided in both the equalization basins and the primary clarifiers. "We immediately saw a greater removal of TSS across the primary clarifier. That was the first sign that NBs brought change. Following that, we saw a reduction in demand for blower air."

Downstream at the aeration basins, this new-found wastewater quality continued to pay off. The oxygen uptake and transfer rates improved as lower surfactant levels gave way to higher oxygen transfer and stronger sanitary bacteria cultures. More efficient oxygen dissolution and happier "bugs" led to a 43% reduction in aeration energy demand, translating to $32,000 in annual savings.

Prior to the nanobubble pilot, GSD implemented a bioaugmentation and biostimulant program to keep the plant's aeration basins running in the face of high surfactant levels. After adding Moleaer's nanobubbles to the treatment process, the district dropped the augmentation program, saving $44,000 in a single year.

Downstream dividends

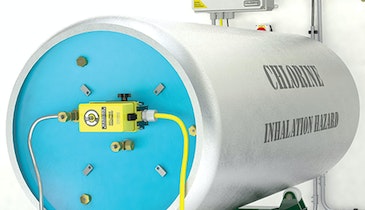

Further along, the higher quality wastewater continued to affect the treatment process past the secondary clarifiers. The reduction of surfactants and organics during the disinfection stage brought a 44% reduction in chlorine demand, saving the district $15,000 per year in chemical costs.

"Greater removal from the primary clarifiers precipitated savings downstream. Chemical and energy use fell as a direct impact of surfactant removal restoring oxygen transfer efficiency, reducing loading, and removing the environmental stress caused by surfactants, leading to a happy plant," says Crisman. "The combination of those three things is where our energy savings come from."

Moleaer's test results found that the NBG 6 pilot removed 40% of total QACs, 54% of total nonionic surfactants, and 51% of total anionic surfactants from GSD's raw wastewater influent. After witnessing the effects on treatment and savings from using the nanobubble generator, GSD decided to keep running their NBG 6 past the initial three-month pilot. The district enrolled in Moleaer's nanobubbles-as-a-service program, letting the manufacturer maintain their nanobubble generator and upgrade the district's units as newer technology is released. GSD's total cost savings are predicted to be $87,000 per year after the costs associated with the permanent installation.

What's next

Equipped with the nanobubble generator, GSD now has access to a new set of innovative options that surfactants previously made impossible to consider. "From a financial perspective, GSD is saving money, but that's only one aspect of how nanobubbles changed things. The plant is more stable and even increased its organic capacity with NBs, offsetting plant upgrade capital expenses," Crisman says. "GSD can now consider other technologies too, like ammonia-based aeration control, for further energy savings at the aeration basins. The district wouldn't have considered upgrades like this, operating in less stable conditions."

New technologies continue to reshape the norms of water and wastewater treatment. Pretreatment with nanobubbles enabled GSD WRRF to change the direction of their plant's capital and operational expenses to a degree that was unthinkable a few years ago. The direct surfactant removal intensified the treatment facility and balanced wastewater quality while reducing traditional chemical addition. "This industry typically uses chemistry as a solution," Crisman says. "I love that we're not bringing chemicals onsite, and nothing is hauled away." Academics and industry are still exploring potential nanobubble generator applications at treatment plants, meaning this is only the beginning for the promising technology.