Interested in Tanks?

Get Tanks articles, news and videos right in your inbox! Sign up now.

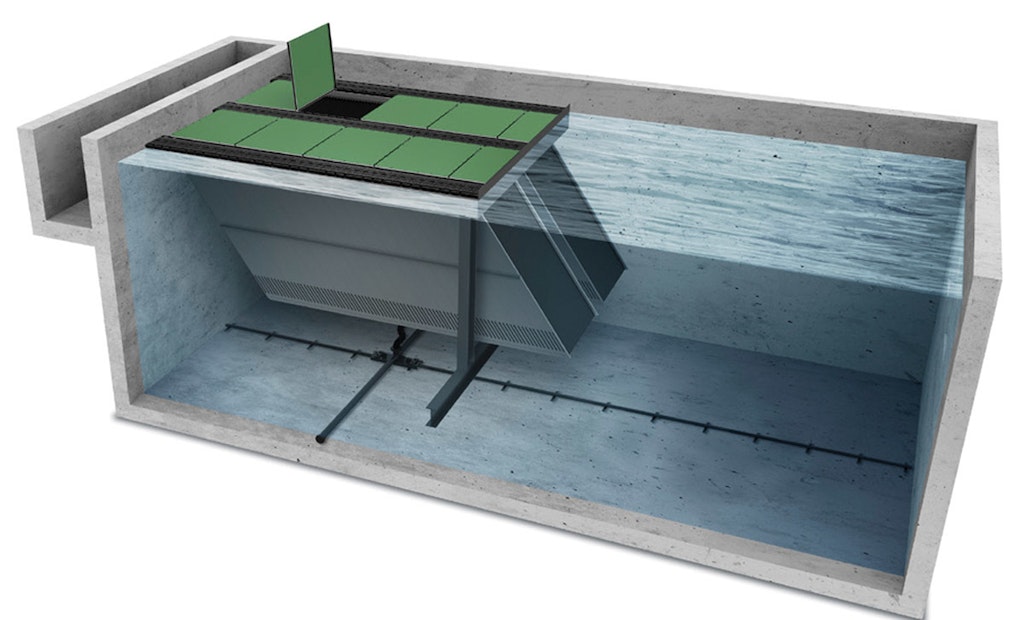

Tanks + Get AlertsThroughout history, sedimentation has served as a tried-and-true method for water and wastewater treatment. That doesn’t mean the technology can’t be upgraded, though. Xylem’s Leopold Texler lamella clarifier is a great example as its lamellae are made from a recyclable, durable, high-density polyethylene geotextile material — which reduces service and maintenance requirements while cutting solids by more than 80%.

The lamella plates typically found in clarifiers are made from heavy stainless steel plates, which require extensive support structures and significant capital investment. According to Matt Schomaker, regional manager — Western NA, Xylem, when exposed to sun, steel reflects UV rays and promotes algae growth in the clarifier, reducing the clarification performance and requiring regular, manual cleaning. “The repellent and flexible nature of the geotextile prevents sludge accumulation on the lamella sheets, which reduces the need for regular cleaning,” says Schomaker.

Lamella sheets are installed at an inclined 55-degree angle. Solids settle as the water travels upward between the lamella sheets and flows through trough covers featuring an integrated v-notch weir, resulting in even distribution of flow throughout the clarifier.

“The inclined plate arrangement of the Texler system allows for an increase in the clarification area and allows for higher surface overflow rates, reducing the required basin dimensions by up to 80% for new builds or allowing more than 100% increase in flow within existing sedimentation basins,” says Schomaker. “The geotextile material has been proven in similar applications to last over 20 years. The width of the lamella sheets can be adapted to optimize use of existing basins.”

As a result, water treatment capacity of existing rectangular clarification systems can be increased by up to 100%, with over 80% reduction in solids and turbidity values reaching levels less than 1 NTU. The solution’s modular design allows for easy maintenance as each lamella sheet can be easily removed independently. The flexible design allows for cost-effective retrofitting of existing rectangular basins, which significantly reduces the overall construction costs while significantly increasing flow capacity.

“With the Texler system we are taking an existing technology and making it lighter, easier to install and more cost efficient,” says Schomaker. “The majority of our construction materials are HDPE-based and the system weight is about 80% lower than stainless-steel plate settler systems.”

Schomaker says that reviews have been positive. “Performance in the field has matched our expectations,” he says. “The system has also been relatively maintenance free with minimal sludge accumulation over time on the geotextile sheets.”

855-995-4261; www.xylem.com/treatment