Hydraulic pumps in this skid are designed to inject a single chemical to four locations (Keen Solutions). Pressure gauges have block valves so that they can be replaced without stopping the system.

Interested in Pumps?

Get Pumps articles, news and videos right in your inbox! Sign up now.

Pumps + Get AlertsAt first glance municipal wastewater treatment seems straightforward. Wastewater flows into the plant, gets purified to permit requirement and is released to the environment or reused.

In reality, treating wastewater is a complex that depends on dosing with chemicals that regulate a variety of parameters and processes. A few of the common chemicals and their characteristics are:

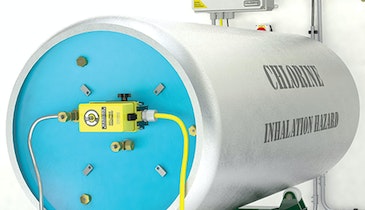

Sodium hypochlorite. Most often used for disinfection, this chemical is among the most difficult to handle as it will corrode most metals and it cannot be mixed or stored with ammonia, acids, organics and reducing agents. It is also challenging for metering pumps because it tends to off-gas and can cause the pumps to become gas-bound. (This does not happen with peristaltic pumps; in diaphragm pumps it can be prevented with special vent valves.)

Sulfuric acid. This acid is used for pH adjustment, mostly in a concentrated form. Concentrated solutions can often be handled with vessels of Alloy 20 or PVDF, while more corrosive dilute solutions require plastics such as PVC or PVDF.

Sodium hydroxide. Also used for pH adjustment, this chemical is supplied 25% to 50% solutions. It is incompatible with metering pump elastomers, such as FKM in O-ring seals. In higher-strength solutions, it tends to gel in pumps left idle for a time. Flush valves or special pump heads can address the issue.

Sodium bisulfite. This common dechlorinating agent requires a mixer to keep it in solution in the metering pump supply tank. Plastics such as PVC and PVDF and metals such as 316 stainless steel are suitable for handling this chemical.

Emulsion polymer. Fed as a coagulant to assist in biosolids dewatering, these chemicals are often extremely viscous and are shear-sensitive once hydrated. Diaphragm pumps with high-viscosity head designs or peristaltic pumps are often required.

Varieties of metering pumps

Faced with this array of chemicals, and sometimes others, each with unique handling and usage characteristics that must be followed to the letter, plant operators must select the most appropriate metering pump technology for each dosing application.

There is no one-size-fits-all solution to metering pump selection. In fact, creating the most efficient, effective and safest chemical-handling most often requires using different pump technologies for different chemicals. Here’s a look at four pump technologies that when deployed properly can play a key role in optimizing treatment operations.

Mechanical diaphragm

Mechanically actuated diaphragm metering pumps offer an ease of operation and startup, making them attractive for many applications. They normally offer lower initial cost than other motor-driven pump designs, especially at higher flow rates, but they can have higher operating costs.

These pumps offer excellent suction lift and can handle liquids such as sodium hypochlorite that off-gas, and more viscous chemicals. This is because the diaphragm is attached to the piston for a positive return, usually aided by a spring. These pumps are somewhat limited in discharge pressure capability, many being around 100 to 235 psi. Repeatable accuracy is about +/-2%. An external relief valve usually needs to be added to prevent damage in over-pressurized situations.

Hydraulic diaphragm

Hydraulically actuated diaphragm metering pumps are well suited for the harshest chemical-handling conditions; they are low-maintenance pumps designed for 20 years of service. This is because most of their moving parts are submerged in a bath of hydraulic fluid.

In addition, the diaphragm is hydraulically balanced meaning that the hydraulic fluid is on the oil side of the diaphragm while the chemical being pumped is on the wetted (or process) side. The piston, internal to the pump, pushes oil against the diaphragm but never directly contacts it. These units can pump against extremely high pressures if need be, so long discharge lines are not a problem.

Hydraulic diaphragm pumps are also equipped with an adjustable internal relief valve that prevent over-pressure and resulting pump damage. They offer a repeatable dosing accuracy of +/-1%.

Solenoid diaphragm

Solenoid actuated (or electronic) metering pumps are a viable economical option for low-flow, low-pressure chemical-dosing. They are generally available to a maximum of 20 gph, and at those capacities maximum pressures are normally about 30 psi. The lower and medium capacities are compatible with pressures of 100 to 150 psi with low flows (less than 1 gph) to over 200 psi. They offer a repeatable dosing accuracy of +/-3%. They normally include an onboard relief valve to prevent pump damage from over-pressurization.

Peristaltic

This pump technology is simple in design and well suited for handling viscous and abrasive chemicals. Because the design includes a rotor with shoes or rollers that squeeze the hose or tube and force the liquid to the discharge port, peristaltic pumps can run dry.

Peristaltic pumps do not have valves that can become clogged. This is important when a pump needs to be shut down during a product run. The lack of valves eliminates clogging especially when handling viscous liquids or those that will solidify or become gelatinous when resting.

Getting assistance

While all these pump technologies can provide significant benefits, the key challenge is knowing which pump is best for each chemical metering application. This is where the pump manufacturer can lend a hand. Many manufacturers also offer most of the components included in a complete chemical-feed system: relief and back-pressure valves, calibration columns, tanks, mixers, injection quills and control panels. While the task of properly outfitting a treatment facility may seem overwhelming, manufacturers of the various components or complete system can be a valuable source of assistance.

The variety of chemicals required for various treatment processes can pose risks for plant operators. With multiple variables to consider, such as flow rates, viscosities, compatibility issues, pH levels and handling characteristics, an array of pump types must be deployed to ensure optimized operations.

Mechanical, hydraulic and solenoid metering pumps, along with peristaltic pumps, have been proven to offer excellent capabilities. When properly applied, these technologies can help overcome operators’ concerns — and the pump manufacturers stand ready to lend a hand, ensuring that treatment systems will reliably operate at the highest level.

About the author: Eulis Ester (eulis.ester@psgdover.com) is product manager with PSG, a Dover company, for Neptune and Abaque products.